According to the U.S. Bureau of Labor, the transportation and warehousing sector has one of the highest rates of injury across all sectors. From heavy lifting to mismanaged rack infrastructure, a warehouse can be a hot spot for accidents. But there are steps that logistics companies can take to reduce their risk.

A rack safety assessment, which seeks to systematically inspect and document the condition of any racks in a warehouse facility, is one of these measures. These assessments look for potential structural damage, the misuse of warehouse racks, and non-compliance with OSHA pallet rack safety requirements. Catching these issues early helps your business avoid contributing to the industry’s incident rate of 4.7 cases per 100 full-time workers.

In this article, we’ll explore the main signs that your business should conduct a rack safety inspection, touching upon the main indicators, the best practices for maintaining compliance, and show you how to choose a rack vendor that can help your business stay audit-ready.

Why Are Regular Rack Safety Assessments Important?

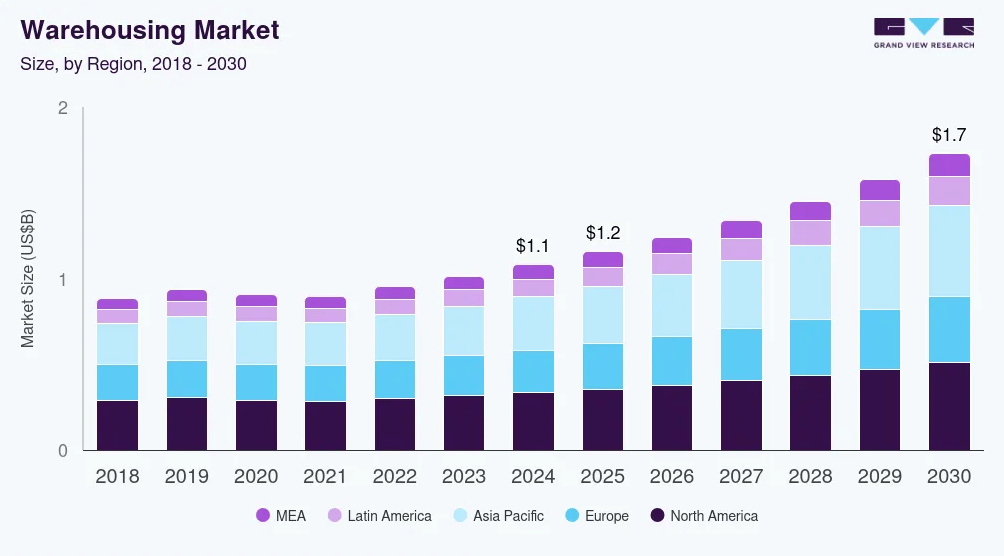

The global warehousing market has grown significantly over recent years, with the North American market dominating over 31% of the international share. Due to the rising need for eCommerce fulfillment spaces, expanding 3PL networks, and an increase in just-in-time inventory models, the industry is expected to continue growing at an impressive 8.1% CAGR.

Source: The growth of the warehousing market, by region, from 2018 to 2030 (predicted).

By 2030, the warehousing market will represent over $1.7 trillion in market value, with this surging value creating a demand in warehouse providers. As warehousing businesses attempt to scale to keep up with this demand, it’s easy for safety considerations to take a backseat.

Yet, as a leading cause of workplace injury, conducting a rack safety inspection is one of the most effective ways of keeping your workers safe while you scale. That’s not to mention the cost-saving potential of avoiding any storage damage, downtime from rack failures, or regulatory fines from OSHA non-compliance.

5 Signs It’s Time for a Rack Safety Assessment

Regularly conducting a rack safety inspection can reduce the likelihood of failure or accidents, protecting your workers and your facilities. If your business isn’t actively monitoring the conditions of your racks, you may fail to notice warning signs of wear-and-tear or structural problems that could lead to disaster.

Here are the five most important signs that you’re overdue for a rack safety assessment.

Visual Structural Damage

Visual structural damage is the most obvious sign that you need to attend to your pallet racks. More obvious damage, like sagging beams or bent braces, signals an accident waiting to happen.

Even more subtle structural damage, like rust or evidence of corrosion, can all point to underlying warehouse safety risks that you need to attend to. If your business notices any deformities, warping, or signs of damage, it’s time to conduct a more extensive racking safety audit.

Missing Load Capacity Labels

OSHA has clear regulations around displaying load capacity labels on pallet racks. Warehouses need to accurately display a shelf or beam load capacity and configuration, as well as include any specific design instructions. Public access data demonstrates that OSHA frequently issues citations for non-compliance with this stipulation.

When reviewing your warehouse pallets, if you notice any missing load capacity labels, this could be a sign that other aspects of regulatory compliance have also fallen by the wayside. Make sure that all pallets are accurately described with tagging labels and uniformly distributed to ensure workers can read them clearly when loading the racks.

Signs of Overloading

Racking limits are set for a reason. As warehouses begin to push beyond the total accorded limit for a pallet rack, you may notice visual signs of their inability to take the weight. Sagging beams or overhanging pallets both suggest that goods are being stored ineffectively. Looking for these signs ahead of time can help avoid any major damages or harm that a collapse would incur.

If you notice any of the signs of overloading, you should immediately seek to reorganize your pallet racks. Going beyond the documented pallet rack weight limit is an accident waiting to happen.

Missing Rack Safety Hardware

Another major sign that your pallet racks need a more extensive safety audit is any missing hardware. Bolts, locking pins, and anchors all ensure a rack is safely structured in place, helping to avoid any accidents or collapses.

When reviewing your racking hardware, look for any missing safety elements. A complete warehouse safety audit will seek out these critical pieces, as even one missing part can lead to a disaster.

OSHA standard 1910.176(b) mandates that any stored material should be stacked and interlocked in place to ensure that it is stable against sliding or collapse. Even if your product is stacked correctly, without proper safety hardware your product could shift and potentially fall due to dislodged beams or loose anchors. Without these critical components in place, it’s extremely difficult to guarantee the safety of any stored goods on your racks.

Unrecorded Repairs or Modification

When a racking provider makes repairs or conducts pallet adjustments without the proper documentation, they may deliver a racking system that no longer aligns with the manufacturer’s specifications. Swapping out beams, welding on new bracers, or significantly changing the weight distribution of a rack can void its weight capacity. If your employees aren’t aware of these changes, they could overload without realizing.

Additionally, if your racking provider makes requested repairs to your pallets in an unsatisfactory way, including hasty modifications or undocumented additions, then this could put you in non-compliance. Where possible, seek out trustworthy, safety-first partners for your warehouse infrastructure needs.

How to Choose a Warehouse Rack Vendor

After conducting a warehouse safety audit, you may quickly realize that your current infrastructure isn’t up to OSHA pallet racking compliance standards. If you’re ready for a change, you’re in the right place.

At Integrity Material Handling Systems Inc., our staff has over 65 years of experience in the sector, having delivered OSHA-compliant pallet racks to businesses that range from start-ups to Fortune 500 giants. By actively collaborating with our clients, we provide the best rack systems at the lowest possible price.

Reach out to the team today to make your warehouse a better place for all.