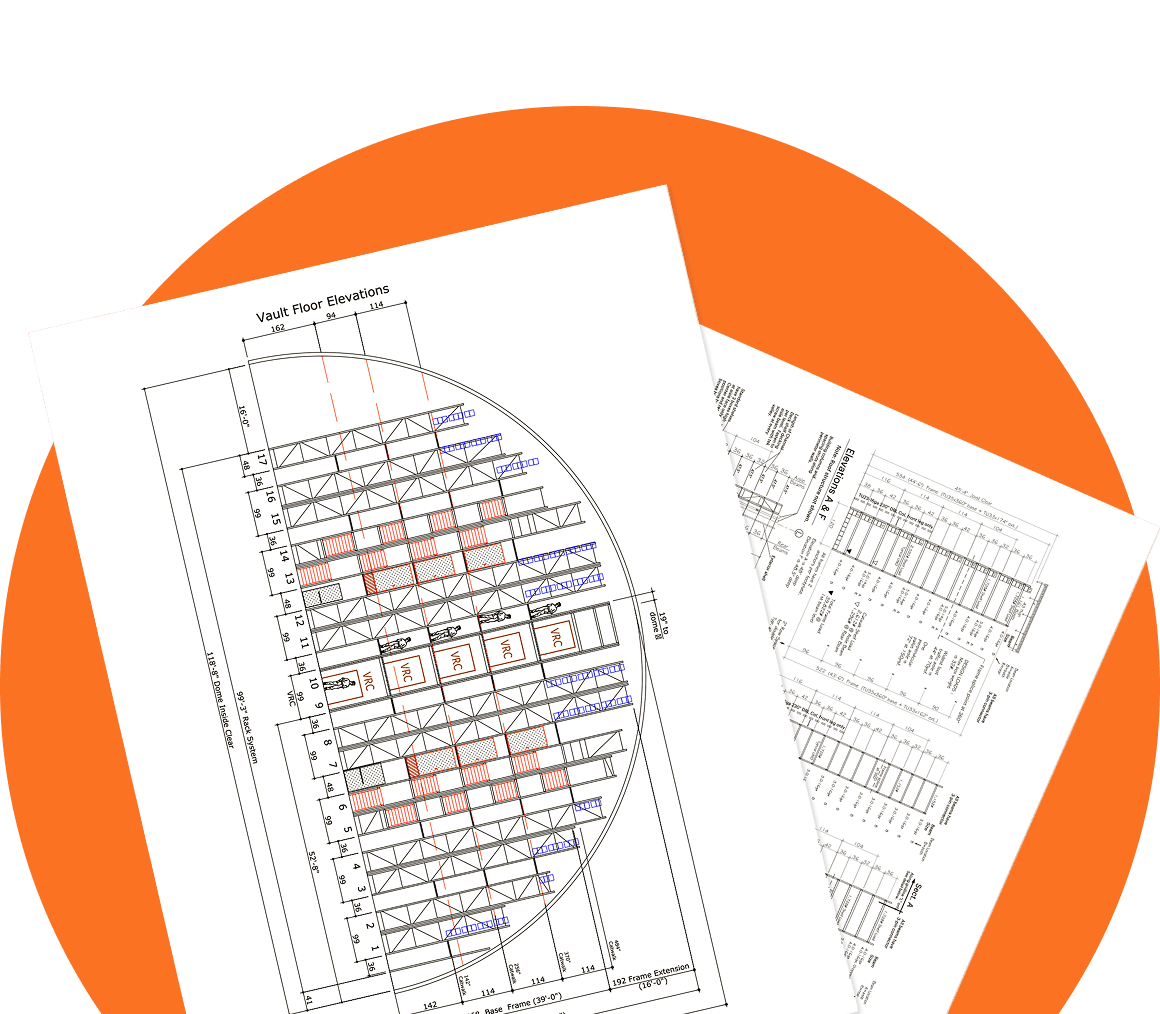

Integrity Material Handling Systems, Inc. offers comprehensive pallet racking solutions tailored to virtually any warehouse or storage need. We provide both new and quality used racking systems to meet a range of budgets and facility requirements. Our team’s consultative approach and decades of experience ensure we can serve a wide variety of industries, from third-party logistics (3PL) providers and distribution centers to food processing companies and electrical supply distributors. Whether your operation is a small startup or a Fortune 500 company, we design pallet rack systems that maximize space, efficiency, and safety, delivering the best storage solution at the right price.

We Offer A Wide Variety of Pallet Rack Systems:

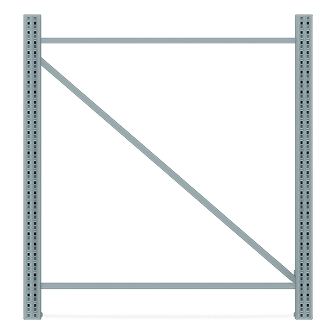

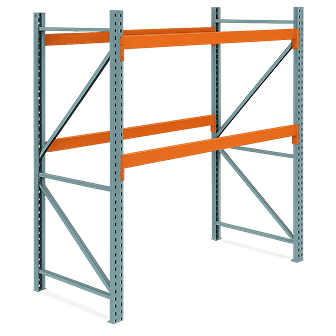

Selective Rack

Selective pallet racking is the most common and versatile type of warehouse rack, designed to allow direct access to every pallet stored. This system typically consists of single-deep rows of racking, meaning forklifts can retrieve any pallet without having to move others, which is ideal for warehouses with many SKUs that require quick, frequent access to products. Selective racks are cost-effective and can be configured in various sizes and load capacities, making them suitable for everything from light-duty storage to heavy-duty industrial applications. They do require more aisle space than higher-density systems, but their full selectivity ensures optimal flexibility for fast-paced operations. Integrity offers selective racking in both new and used options, so you can choose a solution that fits your operational needs and budget without compromising on quality.

Drive-In Rack

Drive-in pallet racking is a high-density storage system that maximizes floor space by eliminating many of the aisles found in selective rack setups. In a drive-in rack system, multiple pallets of the same SKU are stored deep in each bay on continuous rails, and forklifts drive into the rack structure to load and unload pallets from the same entry point. This design greatly increases storage capacity in the same area compared to selective racking. Drive-in racks work best for large volumes of identical or slow-moving inventory, and they typically operate on a last-in, first-out (LIFO) principle, making them especially popular for applications like cold storage or seasonal goods. Integrity can supply drive-in rack systems in both new and used configurations, tailoring the design to withstand forklift traffic and heavy loads while providing a cost-effective, space-saving solution.

Very Narrow Aisle (VNA) Pallet Racking

Very Narrow Aisle (VNA) pallet racking is a high-density warehouse storage system that maximizes vertical space while maintaining 100 percent selectivity. By reducing aisle widths compared to standard selective racking, VNA systems significantly increase storage capacity within the same footprint, making them ideal for space-constrained warehouses and distribution centers. In a VNA rack system, specially designed forklifts operate in aisles as narrow as five to six feet, often guided by rails or wire systems for added precision and safety. This configuration allows operators to access any pallet directly while using the full height of the facility for storage. VNA racking combines the benefits of selective access with dense storage, improving both space utilization and picking efficiency. Very Narrow Aisle pallet racks are ideal for warehouses with high inventory turnover and a large number of SKUs. Common applications include e-commerce fulfillment centers, retail distribution hubs, and third-party logistics providers. Integrity offers VNA racking systems in both new and used configurations, engineered to meet the demands of narrow aisle lift equipment, seismic requirements, and heavy-duty warehouse operations. Our team can tailor each system to your facility, providing a cost-effective, space-saving solution that boosts productivity and inventory control.

Push Back Rack

Push back racking is a dynamic storage solution that stores pallets on inclined rails equipped with nested rolling carts. Each time a new pallet is loaded from the front, it gently pushes earlier pallets back into the lane. When the front pallet is removed, the pallet behind it rolls forward into position by gravity. This system allows you to store multiple pallets deep per lane, all accessible from a single aisle, thus greatly increasing storage density while reducing the number of aisles needed. Push back racks use a LIFO inventory method, making them ideal for warehouses that can manage rotating stock in that manner, for example, distribution facilities with multiple pallets of the same SKU or any operation looking to optimize space for high-volume, fast-moving items. Integrity provides push back rack systems in new or used options and will help determine if this high-density, gravity-fed solution is the best fit for your inventory mix and throughput requirements.

Pallet Flow Rack

Pallet flow racking, also known as gravity flow rack, is a first-in, first-out (FIFO) system that uses sloped roller tracks to move pallets automatically from the loading end to the retrieval end. In a typical pallet flow setup, pallets are loaded at the higher end of inclined tracks and roll forward under controlled speed to the picking side, ensuring that the oldest inventory is always in front for order fulfillment. This style of racking improves storage density and turnover efficiency, as it maintains a constant flow of pallets to the front and minimizes the labor needed to replenish pick faces. Pallet flow racks excel in operations where inventory rotation and high throughput are critical, for instance, in food and beverage distribution or any environment with expiration-dated products. Integrity can design pallet flow systems with new or used components, integrating the appropriate brake mechanisms and flow lanes to match your pallet sizes and weights. The result is a reliable, gravity-driven storage solution that keeps products moving efficiently while fully utilizing your available cube space.

Double Deep Rack

Double deep pallet racking is essentially a back-to-back selective rack arrangement that stores two pallets deep per row, effectively doubling the storage capacity for each aisle of racking. Using the same basic upright and beam components as selective racks, double deep racks place a second pallet immediately behind the first, requiring a special deep-reach forklift to access the rear positions. This design increases pallet density by reducing the number of aisles needed, offering a good middle ground between standard selective and drive-in systems. Double deep racking works best when you have multiple pallets of the same SKU that can be stored together, as the rear pallet will only be accessible once the front pallet is moved. While selectivity is reduced compared to single-deep racks, many warehouses find this trade-off acceptable for the gain in storage efficiency. It’s a popular choice in industries like general warehousing and retail distribution. Integrity offers both new and used double deep rack solutions, optimizing the layout and equipment selection to ensure you get higher storage density and smooth operation tailored to your inventory needs.

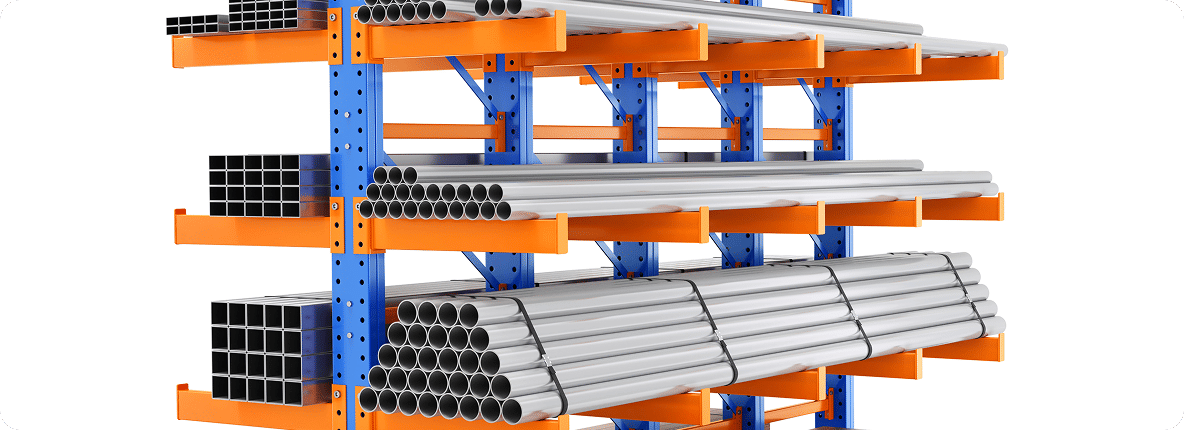

Cantilever Rack

Cantilever racking is a specialized storage rack designed for long, bulky, or awkward items that won’t fit on traditional pallet racks. Instead of vertical front beams, cantilever racks have strong vertical columns at the rear with horizontal arms extending outward, creating open-front shelving that is perfect for products like lumber, pipes, steel bar, furniture, or rolls of carpet. With no vertical obstructions on the loading face, handlers can easily load and unload items of virtually any length. Cantilever systems can be configured as single-sided or double-sided and are built using either roll-formed or structural steel depending on the weight and durability requirements. These racks excel in industries such as construction materials, home improvement supplies, and manufacturing. Integrity stocks new and used cantilever rack components and can design custom cantilever solutions to accommodate your products safely and efficiently. Our experts ensure that the arms, columns, and bracing are properly rated for your load weights and dimensions, delivering a robust storage solution for those hard-to-store items.

Specialty and Custom Racking Solutions

In addition to the common rack types above, Integrity supports a range of less common and specialty racking systems to meet unique storage challenges. This includes everything from carton flow racks to custom-engineered solutions for items with special handling requirements, such as archive shelving or automotive tire racks. Backed by our in-house design capabilities and fabrication partners, we can create tailored racking or hybrid systems that perfectly match your operational needs. Our goal is to ensure every customer gets the right racking solution – whether off-the-shelf or custom – to maximize space utilization, improve workflow, and protect inventory. With Integrity’s deep industry knowledge and commitment to quality, you can trust us to recommend and implement the optimal pallet racking system for your business, every time.

Receive A

Custom Quote